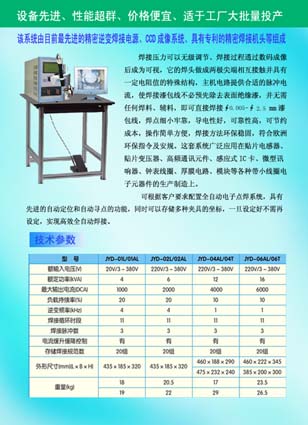

漆包線精密點焊機

地區城市:廣東省 -東莞 更新時間:2012-2-29 16:10:56

聯 系 人: 熊斌 有效期限:2013-2-28 12:44:39

電子信箱:jingyuan_weld@163.com 聯系電話:86-769-23117296

該系統由目前最先進的精密逆變點焊機、專用精密機頭組成,以數字逆變電源作為加熱源,操作界面直觀、簡捷,控制精確,熱量輸出穩定,動態響應快,可對漆包線直接進行點焊。焊點細小牢靠、導電性好、無訊號衰減。焊頭定位準確、使用壽命長。可直接焊接ф0.005-ф2.5mm 的漆包線,焊點細小牢靠,導電性好,可靠性高,可節約成本,操作簡單方便,焊接方法環保穩固,符合歐洲環保指令及安規。這套系統廣泛應用在貼片電感器、貼片變壓器、高頻通訊元件、感應式IC卡、微型喇叭、鐘表線圈、模塊等各種帶小線圈電子元器件的生產制造上。還廣泛應用于漆包線與銅導線(含單或多股裸銅線、單或多股鍍錫銅線、單或多股鍍銀銅線)的精密焊接,漆包線與銅箔的精密焊接。可加裝CCD成像系統。可配置全自動電子點焊系統,實現高效全自動焊接。

優點:設備先進,性能超群、焊接線徑范圍寬,適用面廣,性價比高,適于工廠大批量投產。

Enameled wire dedicated spot welding system

The system is currently the most advanced precision inverter spot welding, precision welding pressure institutions to the number of inverter power supply as a heating source, user interface intuitive, simple, precise control, heat output stability, fast dynamic response can welding wire directly. Little solid welding, resistance of small, non-signal attenuation. Diameter welded to the 0.005-ф2.5mm wire, high reliability, low cost, simple operation, welding methods of environmental protection, in line with European environmental directives and safety regulations. The system is widely used in chip inductors, transformers, high frequency communication components, induction-type IC cards, watches and other coils with small coil of the production of electronic components. Also apply to wire and copper wire (including single-or multi-unit bare copper wire, tinned copper wire, single or multi-unit, single-or silver-plated copper stocks) precision welding, copper wire with precision welding. CCD imaging system can be retro-fitting. Configurable automatic e-spot welding systems, to achieve high-performance fully automatic welding.

Advantages: advanced equipment, superb performance, a wide range of welding wire, the application of a wide range of cost-effective, suitable for mass production factories.